- Back

- TCT Circular Saw Blades

- For Steel Cutting

For Steel Cutting

We can produce the circular saw blades for you.

In case you did not find the type of circular saw blades you require in our catalogue, please contact us. We will make them upon your specification.

METAL SPEED S/C - THROW AWAY TYPE

Cermet tipped (C or CH)

- throw away circular saw blades for structural and low alloyed steels with carbon content less then 0,45% aprox. (750-800 N/mm²)

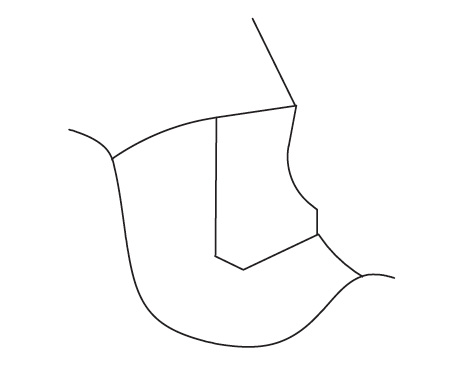

- „H“ version to be applied on non-alloy or alloyed steels with higher tensile strenght (special tooth design, please refer to the sketch below)

TC tipped (S or SH)

- for alloyed steels with more then 0,45% carbon content, high strenght steels (800 N/mm² +), stainless steels, bearing steels, etc.

- „H“ version to be applied on steels with difficult cutting conditions – Ti/Ni based „superalloys“ (special tooth design, please refer to the sketch below)

TYPICAL SIZES AND APPLICATIONS

| Ø (mm) | Kerf/body (mm) | Main bore + pin holes (mm) | Teeth count | Typical application |

|---|---|---|---|---|

| 250 | 2,0/1,75 | 32+4/9/50+4/11/63 40+4/11/80+4/12/64 | 60/72/80 80/90 | solid tube |

| 285 | 2,0/1,75 | 32+4/9/50+4/11/63 40+4/11/80+4/12/64 | 60/72/80 80/90/110 | solid tube |

| 315 | 2,3/2,0 | 32+4/11/63+4/9/50 40+4/11/80+4/12/64 | 60/72/80 80/90/110 | solid tube |

| 350 | 2,7/2,4 | 50+4/16/80 | 80/100/120/140 | tube |

| 360 | 2,6/2,25 | 40+4/16/80+4/12/90 50+4/16/80+4/11/90 | 60/80/100 80/100/120/130 | solid tube |

| 425 | 2,7/2,25 | 40+4/16/80+4/12/90 50+4/16/80+4/11/90 | 50/60/72/80/100 100/120/130 | solid tube |

| 460 | 2,7/2,25 | 40+4/16/80+4/12/90 50+4/16/80+4/11/90 | 40/50/60/80/100 100/120/140 | solid tube |

| 560 | 3,5/3,0 | 50+4/16/80+4/11/90 | 40/50/60/80 | solid |

| 580 | 3,2/2,7 | 80+4/22/120 | 40/50/60/80 | solid |

| 620 | 3,5/2,7 | 50+4/15/80 | 48/60/72 | solid |

| 750 | 3,8/3,2 | 80+4/21/80 | 60/80/100 | solid |

TYPICAL APPLICATION VALUES

Material grade | Solid/tube | Blade type | Cutting speed m/min | Feed speed Fz/tooth | PVD coating |

|---|---|---|---|---|---|

| St37 | Solid | Metal speed C | 110-140 | 0,06-0,08 | |

| 42 CrMo4 | Solid | Metal speed CH | 90-110 | 0,04-0,06 | |

| 44 MnSiV | Solid | Metal speed CH | 90-110 | 0,04-0,06 | |

| C45 | Solid | Metal speed C | 90-110 | 0,05-0,07 | |

| 20CrMo5 | Solid | Metal speed C | 100-125 | 0,06-0,07 | |

| 100 Cr6 | Solid | Metal speed S | 70-90 | 0,04-0,06 | yes |

| 50CrV4 | Solid | Metal speed S | 80-90 | 0,04-0,05 | yes |

| X20Cr13 | Solid | Metal speed SH | 50-90 | 0,04-0,05 | yes |

| St52 | Tube | Metal speed S | 230-270 | 0,04-0,08* | yes |

| E275/355+C | Tube | Metal speed CH | 220-250 | 0,04-0,15* | yes |

* variable feed speed in cut (entry – centre – exit)

IMPORTANT GENERAL INFORMATION

- for cutting of solids and pipes on stationary cutting machines (Adige, Rattunde, ExactCut, Amada, Tsune, RSA, Nishijimax, etc.) and also in bulk cutting. For flying cut-off or orbital cutting/milling machines, please see next pages;

- optional PVD coating (AlTiN, AlTiCrN, etc.) for specific applications (stainless, high Ni content, tubes, Ti based „superalloys“ etc.) is recommended;

- for Ni/Ti based alloys dedicated special cooling fluid must be used, please talk to your supplier!

- dimensions and teeth numbers are on request

- In case that you did not find the type of saw blades you require in our catalogue, please contact us. We will make them upon your specification.

METAL STANDARD

- cutting of solids, tubes and construction profiles (HSS), rail tracks, large billets

- non-alloy or alloy steels, bearing steel

- possibility of regrinding

- number of teeth and type of blade depending on application

- diameter of the blade: from 280 to 1300 mm

TCT Metal standard (typical sizes)

| Ø (mm) | Kerf/body (mm) | Main bore + pin holes (mm) | Teeth count | Typical application |

|---|---|---|---|---|

| 630 | 6,5/5,0 | 80 + 8/27/160 | 60 | rail cutting |

| 720 | 5,5/4,5 | 80 + 8/32/200 | 60/72/80 | large steel billets |

| 760 | 5,5/4,5 | 80 + 8/27/160 | 60/80/100 | steel bilets/thick wall tubes |

| 860 | 7,0/5,5 | 80 + 8/32/200 | 60 | steel billets |

- many other sizes upon request for Linsinger, Wagner, Kasto machines…

METAL CUT

Material: Ferrous & nonferrous metals

Application: Solid materials, pipes, profiles, tubes

Machine: Automatic or manual feed machines

- for quick dividing without cooling of bars, pipes, tubes and profiles made of construction steels or aluminium alloys with aproximate wall thickness 0,5-6 mm

- to be used on cut-off, table saws, radial arm saws and hand-held/dry cut machines with reduced RPM (see table), for example Jepson, Elu, Ryobi, Makita, Milwaukee, DeWalt, Black&Decker, etc…

- special geometry and TCT grade enhances lifetime of the cutting edge, cut quality and multiple use of the saw blade

- TCT tips are resharpenable

| D | S | s | d | z | Geometry |

|---|---|---|---|---|---|

| 180 | 1,8 | 1,4 | 20 | 44 | WZ/FA |

| 190 | 1,8 | 1,4 | 20 | 48 | WZ/FA |

| 305 | 2,2 | 1,8 | 25,4 | 60 | WZ/FA/F |

| 305 | 2,2 | 1,8 | 25,4 | 78 | WZ/FA/F |

| 355 | 2,2 | 1,8 | 25,4 | 66 | WZ/FA/F |

| 355 | 2,2 | 1,8 | 25,4 | 90 | WZ/FA/F |

| D | 160 | 190 | 200 | 250 | 300 | 350 | 400 | 450 |

|---|---|---|---|---|---|---|---|---|

| Recommended RPM | 4000 | 3500 | 3000 | 2000 | 1500 | 1500 | 1000 | 1000 |

Explanation: D-blade diameter (mm), S-tooth width [mm], s-body thickness [mm], d-bore [mm], z-number of teeth

CERMET

- cutting of steel & plastic pipes with a hand machine (T-drill, ExactCut etc.)

- standard steels, stainless, copper, plastics

- cermet tipped circular saw blade for heavy duty applications, saw blade can be sharpened

| D | S | s | d | z | Geometry |

|---|---|---|---|---|---|

| 140 | 1,8 | 1,4 | 62 | 46 | WZ/FA |

| 165 | 1,8 | 1,4 | 62 | 54 | WZ/FA |

Explanation: D-blade diameter (mm), S-tooth width [mm], s-body thickness [mm], d-bore [mm], z-number of teeth