- Back

- TCT Circular Saw Blades

- For Steel Cutting

- METAL SPEED S/C - THROW AWAY TYPE

METAL SPEED S/C - THROW AWAY TYPE

Cermet tipped (C or CH)

- throw away circular saw blades for structural and low alloyed steels with carbon content less then 0,45% aprox. (750-800 N/mm²)

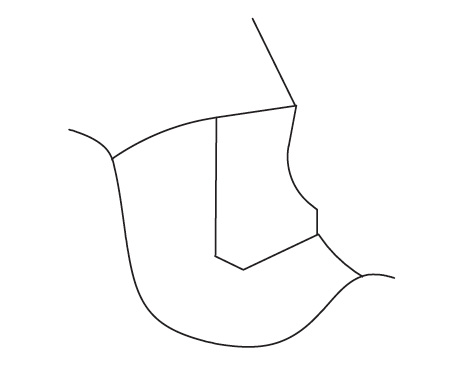

- „H“ version to be applied on non-alloy or alloyed steels with higher tensile strenght (special tooth design, please refer to the sketch below)

TC tipped (S or SH)

- for alloyed steels with more then 0,45% carbon content, high strenght steels (800 N/mm² +), stainless steels, bearing steels, etc.

- „H“ version to be applied on steels with difficult cutting conditions – Ti/Ni based „superalloys“ (special tooth design, please refer to the sketch below)

TYPICAL SIZES AND APPLICATIONS

| Ø (mm) | Kerf/body (mm) | Main bore + pin holes (mm) | Teeth count | Typical application |

|---|---|---|---|---|

| 250 | 2,0/1,75 | 32+4/9/50+4/11/63 40+4/11/80+4/12/64 | 60/72/80 80/90 | solid tube |

| 285 | 2,0/1,75 | 32+4/9/50+4/11/63 40+4/11/80+4/12/64 | 60/72/80 80/90/110 | solid tube |

| 315 | 2,3/2,0 | 32+4/11/63+4/9/50 40+4/11/80+4/12/64 | 60/72/80 80/90/110 | solid tube |

| 350 | 2,7/2,4 | 50+4/16/80 | 80/100/120/140 | tube |

| 360 | 2,6/2,25 | 40+4/16/80+4/12/90 50+4/16/80+4/11/90 | 60/80/100 80/100/120/130 | solid tube |

| 425 | 2,7/2,25 | 40+4/16/80+4/12/90 50+4/16/80+4/11/90 | 50/60/72/80/100 100/120/130 | solid tube |

| 460 | 2,7/2,25 | 40+4/16/80+4/12/90 50+4/16/80+4/11/90 | 40/50/60/80/100 100/120/140 | solid tube |

| 560 | 3,5/3,0 | 50+4/16/80+4/11/90 | 40/50/60/80 | solid |

| 580 | 3,2/2,7 | 80+4/22/120 | 40/50/60/80 | solid |

| 620 | 3,5/2,7 | 50+4/15/80 | 48/60/72 | solid |

| 750 | 3,8/3,2 | 80+4/21/80 | 60/80/100 | solid |

TYPICAL APPLICATION VALUES

Material grade | Solid/tube | Blade type | Cutting speed m/min | Feed speed Fz/tooth | PVD coating |

|---|---|---|---|---|---|

| St37 | Solid | Metal speed C | 110-140 | 0,06-0,08 | |

| 42 CrMo4 | Solid | Metal speed CH | 90-110 | 0,04-0,06 | |

| 44 MnSiV | Solid | Metal speed CH | 90-110 | 0,04-0,06 | |

| C45 | Solid | Metal speed C | 90-110 | 0,05-0,07 | |

| 20CrMo5 | Solid | Metal speed C | 100-125 | 0,06-0,07 | |

| 100 Cr6 | Solid | Metal speed S | 70-90 | 0,04-0,06 | yes |

| 50CrV4 | Solid | Metal speed S | 80-90 | 0,04-0,05 | yes |

| X20Cr13 | Solid | Metal speed SH | 50-90 | 0,04-0,05 | yes |

| St52 | Tube | Metal speed S | 230-270 | 0,04-0,08* | yes |

| E275/355+C | Tube | Metal speed CH | 220-250 | 0,04-0,15* | yes |

* variable feed speed in cut (entry – centre – exit)

IMPORTANT GENERAL INFORMATION

- for cutting of solids and pipes on stationary cutting machines (Adige, Rattunde, ExactCut, Amada, Tsune, RSA, Nishijimax, etc.) and also in bulk cutting. For flying cut-off or orbital cutting/milling machines, please see next pages;

- optional PVD coating (AlTiN, AlTiCrN, etc.) for specific applications (stainless, high Ni content, tubes, Ti based „superalloys“ etc.) is recommended;

- for Ni/Ti based alloys dedicated special cooling fluid must be used, please talk to your supplier!

- dimensions and teeth numbers are on request

- In case that you did not find the type of saw blades you require in our catalogue, please contact us. We will make them upon your specification.

Tool advisory centre for circular saw blades, band saws for wood cutting

Have you not found the most suitable tool for your application?

Please, contact us, we will make them for you.